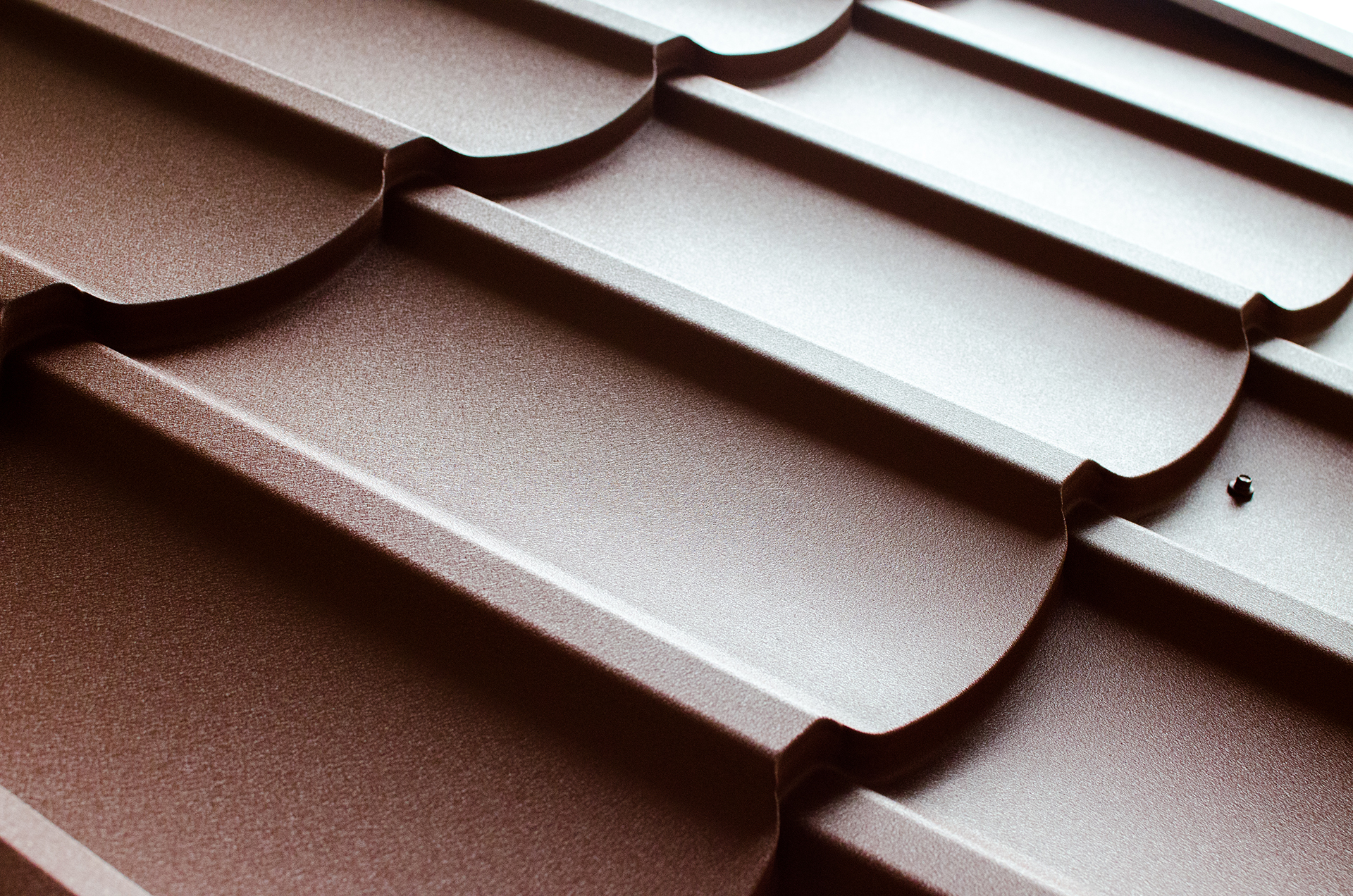

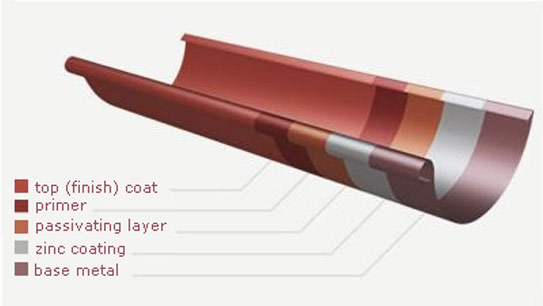

Metal tile panels are a graceful and durable roofing material, suitable for pitched roof applications. They combine the traditional look with the latest technology and can be used on residential and commercial buildings, and for replacing old roofs. Metal tile panels are made from sheet metal which is zinc-plated on both sides, with several protective layers, which ensures durability. It is one of the most light-weight roofing materials, which is an advantage because it does not require a heavy roof support structure.

Head Office, Manufacturing Facility and Showroom: 531 Shaw Road, Dorchester (London), ON N0L 1G4, Canada

Manufacturing Facility and Showroom in Ottawa Area: 5649 Power Rd #4, Ottawa, ON K1G 3N4, Canada

The weight of the material is particularly important for re-roofing old buildings, since light-weight metal panels do not require reinforcing the supporting structures. One square (10'x 10') of metal roof weighs 96 lb., which is about 3 times lighter than traditional clay tiles.

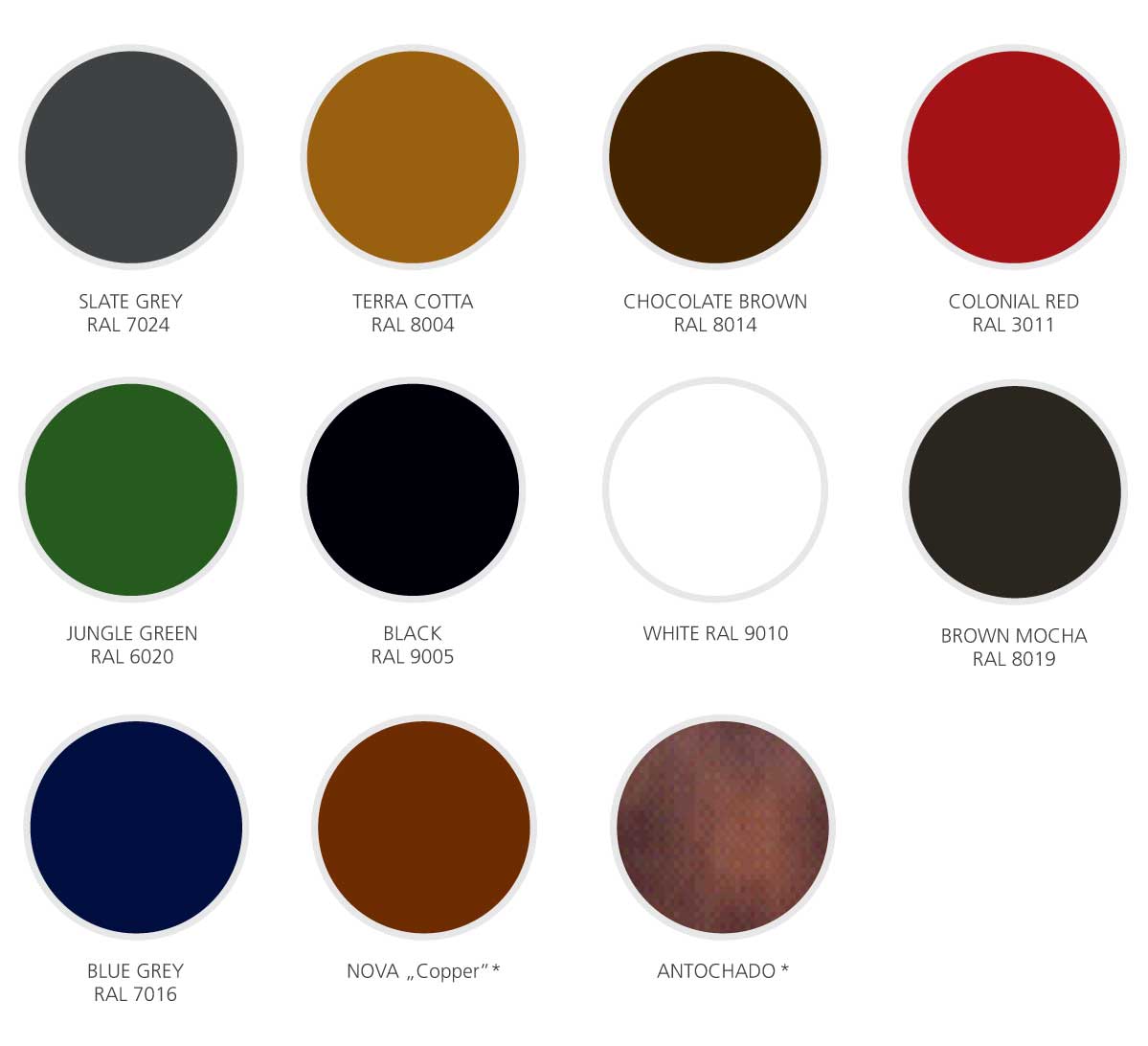

A wide range of colours and roof profiles allow the matching of the roof to the exterior of the

building

and its surroundings. The length of the tile panels are cut to an optimal size to eliminate wastage

and

keep the client's cost as low as possible.

CONTACT US TODAY FOR MORE

INFORMATION

London ECO-METAL Manufacturing Inc. is using steel from North American suppliers and is able to provide 40-years warranty on paint for this new material.

SPECIFICATION DATA SHEET - Roof Ventilation PDF

Recommendation by London Eco-Metal manufacturing Inc on roof ventilation.

Standard, steel material 26 gauge - G90 or 25 gauge (275g / m ). Aluminum material 0.6mm or .024 in. Special order, steel 29 gauge available for T-18 product only. For other gauge of material check with the manufacturer.

Perfect Product for Do-It-Yourself Metal Roofing

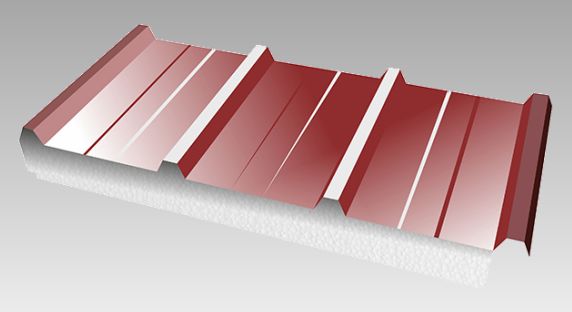

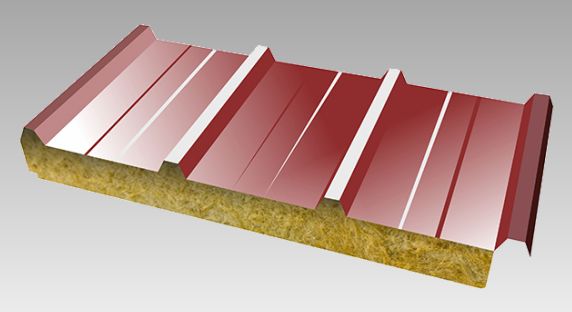

Standing seam has become a popular choice in residential applications because of its modern and clean look. In addition to the sleek, straight lines of this profile, this option offers hidden fasteners.

Modular-type roof-tile sheet, is an innovative and unique product designed for roofing. It is distinguished by its unique shape - 5 bottom waves and 6 peaks, and it has specially formed edges that allow for easy assembly. Sheets join to each other perfectly on the roof. Specially designed sheet front edge allows free-drainage of water condensate and air circulation.

Metal tile panels that bring beauty, durability and reduced energy costs. They offer superior and reliable protection against sun, rain, wind, and snow without sacrificing their striking visual beauty. They complement any home's architecture from Victorian to Contemporary.

Metal tile panels created as a classic design replicating traditional (clay) ceramic tiles. They bring beauty, durability and reduced energy costs and offer reliable protection against sun, rain, wind, and snow without sacrificing their striking visual beauty. They can complement the architectural style of any home from Classic to Contemporary.

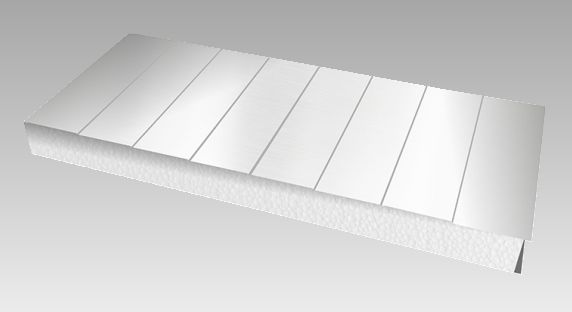

Ribbed metal panels are suitable for lower sloped roofs and other exterior applications.

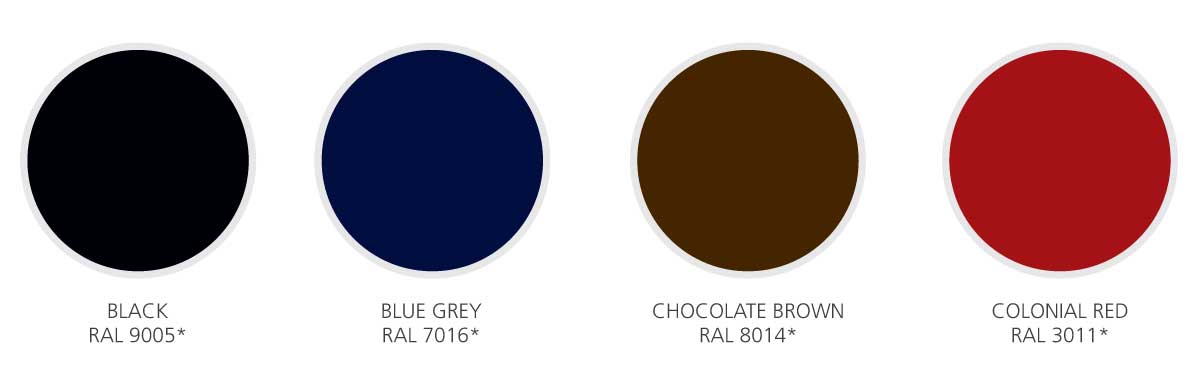

* premium colours

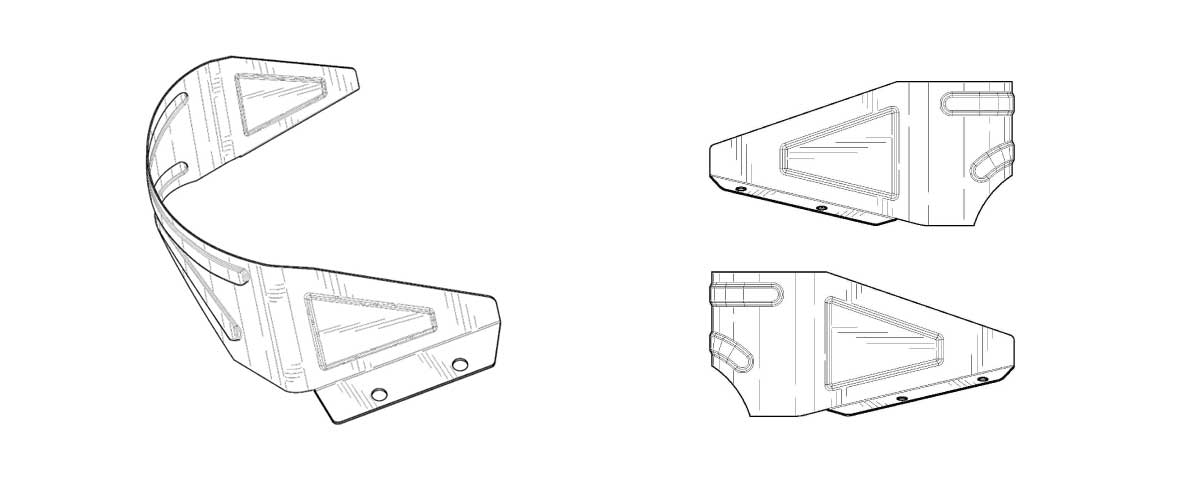

London Eco-Metal Manufacturing Inc. requested the registration of a design for a Snow Guard of which the applicant is the proprietor.

Application number in Canada: 169755

And holds US Patent. Date of the pantent: Sep.3, 2019. US Patent No.: D858,277 S

If you intent do advertise roof jobs with our snow guards installed you need a permission from London Eco-Metal Manufacturing Inc. Contact us for more details or to request a permission.

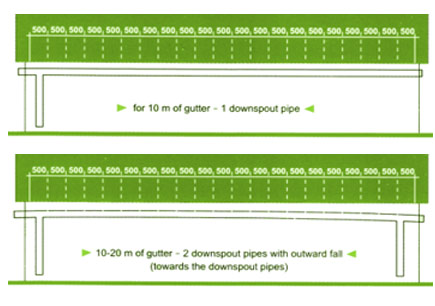

To facilitate bending hangers with the fall to the downspout, mark with a pencil, spots where hangers shall be bent. Remember to number the hangers.

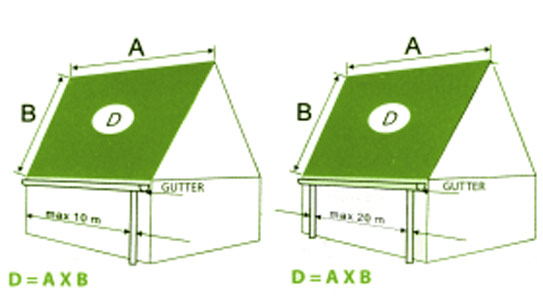

The minimum recommended fall is 2-5 mm per 1 meter of gutter. Assembly of hangers should begin by fixing the first and the last hanger and extending a rope between them. It should indicate a straight line along which other hangers shall be fixed by screwing to the fascia board or to the rafter with at least 2 screws.

For more info on warranty visit Documents page.

We offer a transferable 55 year warranty. We are one of only three companies that have a warranty with the paint manufacturer - Beckers. Beckers provide London Eco-Metal Manufacturer the BeckryTech material produced by ArcelorMittal in Canada under the trademark Granite Deep Mat.

Steel materials have an automatic guarantee provided by the manufacturer, (G90 or 275 g/m2). The guarantee applies automatically from the moment the product is delivered to the client, so there is no paper guarantee issued to the client. The automatic guarantee is not conditional upon mandatory annual maintenance inspections. For roofing applications, the slope of the roof has to be a minimum of 3/12 and the guarantee is not dependent on roof orientation. Freedom of part design is covered by the guarantee.

| Property | ASTM Method | Granite® Deep Mat | |

|---|---|---|---|

| Film Thickness | D5796, D1005, D4138 | Mil | 1.0 +/- 0.2 |

| Formability/Adhesion (T-Bend test) | D4145 | 2T no taped removal | |

| Gloss (60 degree) | D523 | GU | <6 |

| Film integrity | 40 years | ||

| Colour Change | D2244 | Vert. | 30 years – dE 5 max |

| Non-Vert. | 30 years – dE 8 max | ||

| Chalking | D4214 (Method A) | Vert. | 30 years – 8 min |

| Non-Vert. | 30 years – 6 min | ||

| Geographical Limits | Canada and Continental U.S. | ||

| Application Guide | Granite® Deep Mat | ||

| General market application | Product application |

Residential

and commercial buildings, roof panels (tile profiles) |

|

| Climates, country, regional localisation | Weathering requirement |

Typical

UV and temperature conditions in North America. |

|

| Environments, air pollution, chemicals resistance | Corrosion requirement |

Normal environments (rural, urban and light industrial) |

No, thanks to Newsletter. Just get me directly to the Promo Entry Form